Nowadays, we experience a lot of discourse around the 3D printing industry and its advances since its inception in the 1980s. 3D printers have revolutionized many industries, one of them being the architecture and design.

Architecture covers both the process, planning, design and construction of physical structures. These three stages, the work process of an architect, are really benefited by this technology. Simultaneously, we talk about the many benefits it represents for planet Earth, in terms of reducing the carbon footprint.

But, do we actually understand how 3D printing works?

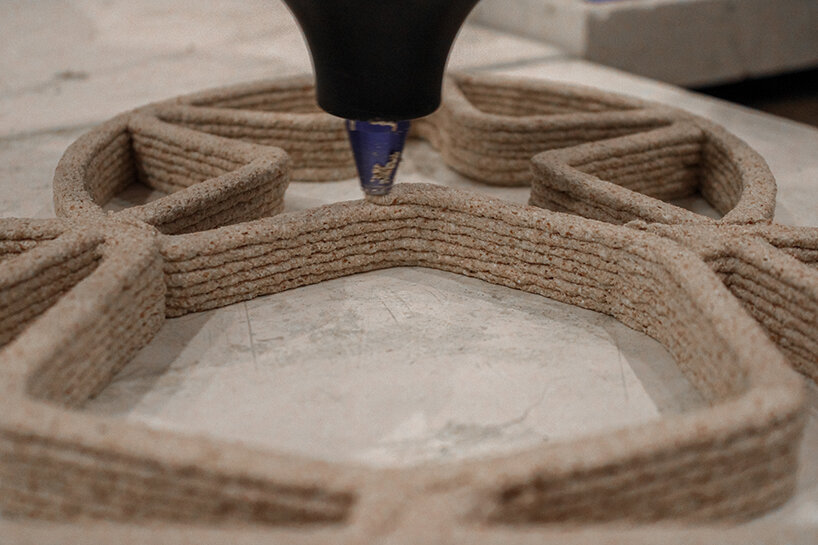

There are multiple realization models, all related to how the material is deposited to create the final object. The material is heated until it becomes liquid and then deposited through the print nozzle. Using information from CAD or modeling software, the design is “sliced” into 2D sections so the nozzle knows where the material should go. The nozzle places the material in thin layers, depending on the scale of the project.

The traditional production process is not considered sustainable. Global waste is at an all-time high: approximately 1.3 billion tons of waste per year is expected to increase to 2.2 billion tons in just 3 years. The first indication that this technology could represent a more sustainable future is the use of recycled materials to produce the product. Up to 95% of the materials used in 3D printing are derived from other resources.

Along with recycled materials, bio-based polymers, commercial and industrial products composed entirely, or in significant part, of biological or agricultural materials, can be used. Bio-based polymers require a lower temperature that can reduce the amount of energy consumed during printing.

Another benefit that this technology points to in contributing to the improvement of our future is the increase in the efficiency of the production process, as well as the time and energy needed to get the products to their destination.

We spoke with Manuel Jiménez García, co-founder of the Spanish design studio Nagami about 3D printing and its role in creating a more sustainable planet. Nagami is a studio that explores the future of design in a new technological era, through research and innovation.

Is 3D printing the route to a more sustainable future?

Absolutely. First of all, 3D printing is an incredibly clean technology. It establishes a really short production chain (from a digital file to the printer). It is compact and versatile, allowing the creation of multiple objects with a single machine, avoiding the need to keep stock. With 3D printing we can produce on demand, expending material and energy only when needed.

As 3D printing scales up, it is becoming a real alternative to most of the industrial processes we currently use, introducing distributed manufacturing that greatly reduces CO2 emissions from long-range shipping.

The other major contribution to the environment is related to the material used. In particular, as the scale of 3D printing with recycled plastics increases, it increases the demand for that material and therefore accelerates the process of cleaning up our landfills and oceans as the number of requests for waste material multiplies.

Will 3D printing be able to replace conventional forms of construction and design?

We are still in the early days, but we have seen 3D printing evolve from prototyping and household items to furniture, large-format sculptures, interiors and facades. As 3D printing enters the design and architectural domain, new solutions for structural parts and building elements will emerge, leading to the progression of this technology to take on a much larger role in the construction industry.

What are some of the disadvantages you can perceive?

Large-scale 3D printing is still quite experimental, even if it allows much more geometric freedom than traditional manufacturing, it has some limitations for use in some applications. While desktop 3D printers can use support materials and mix different finishes in the same print, large-scale 3D printing technology is still much more limited.

On the material front, there is also room for improvement. Research on polymers and recycling technology is evolving rapidly, allowing for greater flexibility in finishes, fire protection and strength. It is still too early to think that recycled plastic will replace reinforced concrete or yet, but we are definitely sailing to become a real more sustainable alternative soon.

3D printing is an industry that has a long, long way to go. We need to finish understanding what the implications will be on the industry. As scientists and professionals continue to work on this manufacturing marvel, they will develop new and better ways to generate less waste and use less energy, making it more sustainable.

Leave A Comment