Striatus, is a project created by Zaha Hadid Architects together with ETZ Zurich, developed by Block Research Group, the company incremental3D and Holcim. Striatus is a 3D printed bridge exemplifying a circular economy and with sustainability at its core as part of its development. It is a design that bases its strength on geometry, reviving the traditional techniques of the masters of the past, all in a structure that stands alone by compression. Undoubtedly, a project that places its strength in technology.

3D printing, although been around since the mid-1980s, has emerged in recent years as exemplary proof of what mechanization of architecture is. It is the process of creating physical objects from digital models. This is achieved by the juxtaposition of materials to create the physical object in its entirety.

How did 3D printing start? This process has multiple origins.

In 1980, Japanese car designer Hideo Kodama was looking for a new method for fast prototyping. Kodama applied for a system patent that used resin and a laser beam. At the time, it was the first patent filing for a system that resembled what 3D printing is today.

It wasn’t until 1984 that a patent was filed in France for a stereolithography, or SLA, process known as optical fabrication (what now is 3D printing) by French inventors Alain Le Méhauté, Olivier de Witte, and Jean Claude André.

That same year, Colorado inventor Charles Hull also filed his patent for a process he called “Apparatus for Production of Three-Dimensional Objects by Stereolithography.” Hull was also looking for a quick way to produce small custom pieces while doing his job at a furniture factory. He developed a prototyping system in which he cured photosensitive resin under an UV lamp until he created the prototype, layer by layer. Finally, he obtained his patent in 1986 and later he founded his company called 3D Systems, one of the largest 3D printing companies today. “Chuck” Hull revolutionized the 3D printing industry and sparked one of the biggest waves of innovation in decades.

After the invention of SLA, numerous technologies were developed, such as Selective Laser Synthesizing or SLS, a patent registered in 1988 at the University of Texas, and later, fused deposition modeling or FDM in 1989, also patented in the United States.

In the 1980s, inventors and designers created the foundations on which this technology is built. Today, there are other techniques of 3D printing in all industries. Some of these are: Digital Light Process (DLP), Multi Jet Fusion (MJF), PolyJet, Direct Metal Laser Sintering (DMLS), and Electron Beam Melting (EBM), among others.

In architecture, companies and professionals began to experiment with design and 3D printing several years ago. Nowadays, we find from cabins and facades to modular and prefabricated structures created under one of these aforementioned techniques. Many of them noted the numerous benefits that the creation of the object under digital modeling brings.

The architecture, design and construction sector is one of the most polluting industries, responsible for 40% of greenhouse gas emissions. For this reason it is crucial to evaluate the use of 3D printing in architecture. This process reduces the consumption of materials in the prototyping and production stage due to the substantial increase in the precision which leads to a limited use of resources. This translates into cleaner, less wasteful and greener processes.

Other benefits this technology offers us is the high customization and the design freedom that it provides to architects and designers. It lends versatility, beneficial when modeling and testing from the simplest to the most complex designs. 3D printing indirectly provides a synergy between space and product, by allowing the malleability and easy correction of errors.

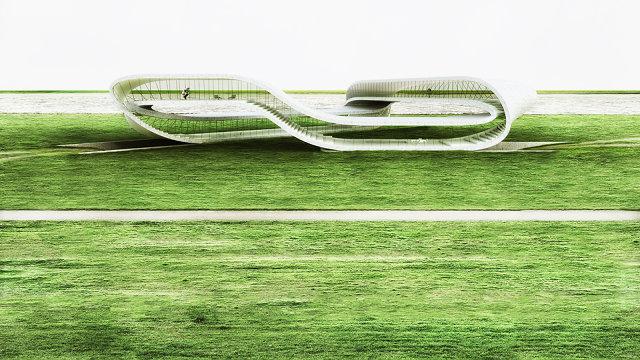

In 2013, Landscape House came to life as the first 3D-printed architectural project, by Dutch architect Janjaap Ruijssenaars and his Rotterdam-based firm Universe Architecture. This project was not intended to be created with a 3D printer, but Ruijssenaars concluded that for many reasons, it was the best way to carry it out.

Together with the Royal Bam Group, a Dutch construction company based in Bunnik, Netherlands, they designed a giant printer called the 3D Builder, the first of its kind in which printing technology is linked to robotics from the automotive industry. Both the printer and the design were pioneers in the use of 3D printing in architecture.

Currently, one of the largest 3D printing projects is underway, designed by HANNAH Architects together with the digital printing company COBOD, specifically the largest project built in the United States. This 4,000-square-foot residential home showcases the possibilities of 3D printing technology, mass customization, and design solutions that integrate conventional construction methods.

While North America leads in terms of the number of 3D printed buildings, Europe and the Middle East both are leaders in the use of 3D printing technology to create ever larger buildings. At 9.9 M in total height, the Saudi Arabian Village is the world’s tallest on-site 3D printed building, part of the Saudi Arabia 2030 project.

As a next step, comes urban planning, and the integration of advanced methods for the construction of bridges, parks, towns and even 3D printed cities. 3D printing supports human understanding of the spatial aspects of a physical environment where many concerns interact when integrating a work into its surroundings.

3D printing is a milestone and an essential piece in the development of the mechanization of architecture. Without a doubt, it evokes futuristic themes and opens the conversation to other topics, such as robotics and even the use of artificial intelligence, which we will be covering in Pertanto very soon.

What are your thoughts on 3D printing? Could it be next for a more sustainable future? What do you think is the next step?

We read you.

Leave A Comment