Scientists from Texas A&M University and Sandia National Laboratories in New Mexico have observed how metal cracks and fuses back together, in a discovery that could pave the way for self-repairing machines, vehicles, and bridges.

Published in the scientific journal Nature, the research demonstrates that metal can self-repair microscopic cracks that form when the material is repeatedly subjected to stress.

This is achieved through a process known as cold welding, which means that no heat or electricity is required. The breakthrough could have significant implications in engineering, argues the report, as 90 percent of mechanical failures result from fatigue in metal components, which occurs when repetitive stress causes cracks to form.

By harnessing the self-repair process and adjusting the microstructure of metals accordingly, scientists predict that it might be possible to prevent fatigue-induced cracking.

Cracked piece of metal healed itself in one experiment. Courtesy of Luis Diaz Devesa

“With that knowledge, we can envision adapting the microstructure to harness self-repair in technological applications, for example, to create materials that are more resistant to fatigue damage,” they explained.

Scientists have been investigating the potential of self-repairing materials for some time. Most breakthroughs have occurred in the development of plastics, such as projects like a self-repairing “e-skin” developed by scientists at the University of Colorado Boulder, although a recent MIT study also found this to be possible in concrete. Until now, this property had not been observed in metals without preheating them.

The study demonstrates that this can be achieved at room temperature under vacuum conditions, in a process known as cold welding, primarily used in electronics and spacecraft technology.

This happens when two bare pieces of metal come so close that their atoms are attracted to each other, causing their surfaces to fuse. It is only possible if the metals are completely clean. It was observed how a crack fused back together, leaving no trace and eventually reopening in a different location.

“What we have confirmed is that metals have their own intrinsic, natural ability to heal themselves, at least in the case of fatigue damage at the nanoscale,” said Boyce, who is also a co-lead author of the study. The report states that the discovery “challenges the most fundamental theories on how engineers design and evaluate fatigue life in structural materials.”

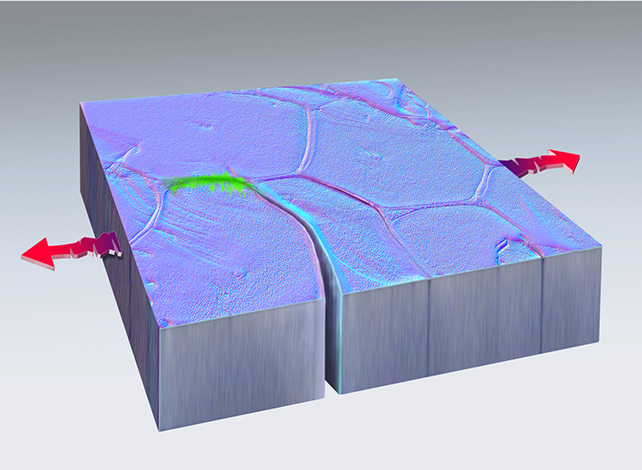

Diagram showing tensile forces (red arrows) created a crack that healed (green) in platinum metal. Courtesy of Dan Thompson National Laboratories

The next steps will be to explore whether metal can self-repair when exposed to air, not just in a vacuum, and whether the process is possible for metal alloys like steel.

“The most important short-term consequences are for fundamental theories of fatigue in metals,” the researchers explained. “These will have to be revised to take crack healing into account.”

Leave A Comment