In the realm of modern architecture, innovation and sustainability have become inseparable companions. As we strive to create structures that not only push the boundaries of design but also minimize environmental impact, the concept of self-healing materials emerges as a groundbreaking advancement with the potential to reshape the way we construct and maintain buildings. These cutting-edge materials, inspired by the regenerative abilities of natural systems, promise enhanced durability, reduced maintenance costs, and a significant decrease in resource consumption.

The notion of self-healing materials has its roots in the idea that structures can possess an inherent capacity to repair and regenerate in response to damage. This concept takes inspiration from biological systems that demonstrate remarkable self-healing abilities. Imagine the human body healing a wound or a tree regrowing a lost branch. Engineers and materials scientists have sought to replicate these biological principles in synthetic materials, paving the way for a new paradigm in architectural design.

One of the most promising aspects of self-healing materials is their potential to address the ubiquitous issue of infrastructure deterioration. Traditional construction materials, such as concrete and steel, are susceptible to various forms of degradation over time, including cracks, corrosion, and wear. The consequences are far-reaching, resulting in high maintenance costs, shortened lifespan of structures, and environmental concerns due to resource-intensive repair processes.

Smartpol, developed by a team at the University of Alicante. A polymer that stands out for its self-regeneration power and its elastomeric features.

Self-healing materials are key to mitigating these challenges. Imagine a concrete façade that can automatically repair small cracks caused by environmental stresses, or steel beams that can regenerate protective layers to prevent corrosion. The implications are profound, not only in terms of extending the lifespan of buildings but also in contributing to a more sustainable built environment.

Self-Healing Concrete. Courtesy of Arcus Global

One of the notable mechanisms used in self-repairing materials is the incorporation of microcapsules within the material matrix. These tiny capsules contain healing agents that are released when damage occurs, sealing cracks and restoring structural integrity. In the context of architecture, this technology could be applied to concrete, where microcapsules containing specialized chemicals could be distributed throughout the mixture. When cracks form due to stresses or environmental factors, these capsules rupture, releasing the healing agents to repair the damaged areas.

Furthermore, self-repairing materials offer architects and designers an unprecedented freedom in their creative endeavors. The ability to integrate these materials into innovative designs not only enhances structural integrity but also opens up new avenues for artistic expression. Architects can experiment with complex shapes, daring cantilevers, and intricate facades, knowing that the inherent self-repair capabilities of the materials will help maintain the integrity of their vision over time.

Sustainability is a cornerstone of contemporary architectural discourse, and self-repairing materials align perfectly with this ethos. By reducing the need for frequent repairs and replacements, these materials contribute to a significant reduction in the consumption of raw materials and energy. The construction industry is known for its resource-intensive nature, but self-repairing materials have the potential to reverse this trend by promoting resilient and longer-lasting structures.

In addition to their direct impact on structural integrity, self-repairing materials also offer a more comprehensive approach to sustainable architecture. Take, for example, the water consumption associated with traditional construction methods. The process of mixing and curing concrete requires substantial amounts of water. Self-repairing concrete, with its potential to reduce cracks and deterioration, could lead to less water usage over the lifespan of a building.

However, like any innovative technology, self-repairing materials are not exempt from challenges. Research and development continue to optimize their performance, scalability, and cost-effectiveness. Questions related to the long-term durability of healing mechanisms, the integration of these materials into existing construction practices, and the economic feasibility of implementation remain subjects of exploration.

As architects and researchers continue to explore the possibilities of self-repairing materials, the future of sustainable architecture looks increasingly promising. The combination of design innovation and ecological responsibility has the potential to usher in a new era where buildings not only harmonize with their surroundings but also actively contribute to the well-being of the planet. Self-repairing materials represent a leap forward in the quest for resilient, durable, and environmentally-conscious architectural solutions. As we stand at the crossroads of technological advancement and sustainable design, these materials hold the key to unlocking a future in which our built environment heals itself, leaving a positive legacy for future generations.

Here are some examples that demonstrate the use of innovative and sustainable design principles through self-repairing materials:

1. Self-Repairing Concrete Canoe, TU Delft, Netherlands: The Delft University of Technology in the Netherlands developed a concrete canoe with self-repairing concrete that contains bacteria producing calcite when the concrete is damaged. This helps seal cracks and improve the concrete’s durability.

2. The Remembering Material, University of Colorado Boulder, USA: In a research project, the use of self-repairing polymers was explored in the design of a temporary pavilion. The polymers contain microcapsules of healing agents that are activated upon rupture, allowing the material to self-repair in response to damage.

The canoe made of geopolymer concrete, also known as cement-free concrete. Courtesy of TU Delft.

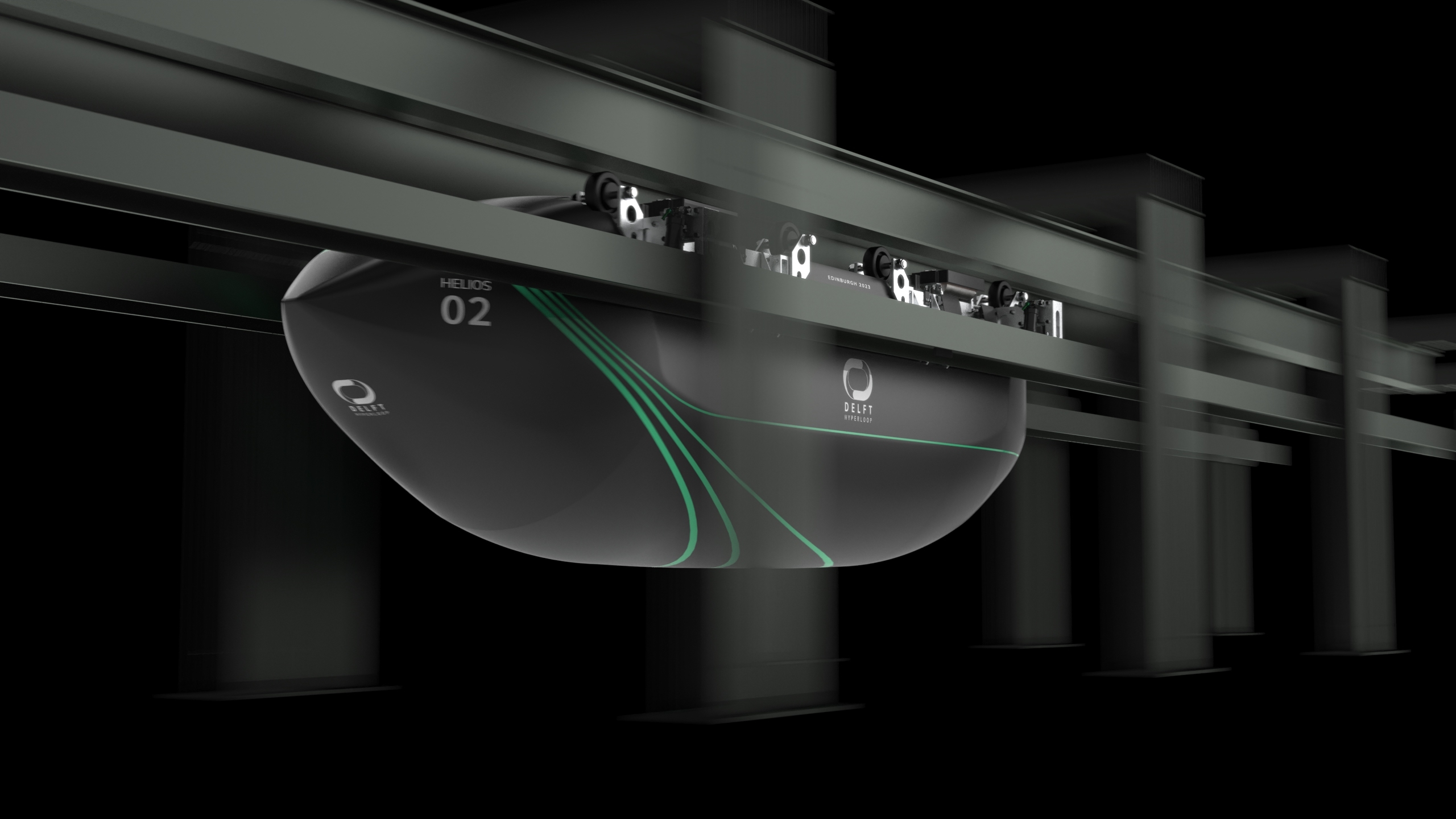

Hyperloop Prototype. Courtesy of Delft

3. Delft Hyperloop, Netherlands: At TU Delft, a team of students designed and built a high-speed transportation prototype known as the Hyperloop. The vehicle included self-repairing materials in its structure, which could be crucial for maintaining the system’s integrity.

4. Self-Repairing Concrete Bridge, Cardiff University, UK: Researchers from Cardiff University worked on developing a self-repairing concrete bridge. Microcapsules with healing agents are incorporated into the concrete, allowing the material to automatically repair itself when cracks form.

5. 4D Printing with Self-Repairing Materials, University of Southern California, USA: While not a building itself, this research explores the possibility of using self-repairing materials in 4D printing, where printed objects can change over time in response to stimuli, such as damage.

It’s important to note that while these examples demonstrate promising advancements in self-repairing material research, widespread implementation in architectural projects is still in its early stages. The technology and understanding of these materials continue to evolve, and it’s possible that in the future, we will see more buildings utilizing these materials to achieve greater durability and sustainability in the construction industry.

fine